Introduction

In the face of escalating environmental concerns, industries worldwide are seeking sustainable alternatives to traditional packaging materials. Baheti Group, a leading manufacturer of polypropylene (PP) woven bags, has taken significant strides in this direction by adopting BOPP (Biaxially Oriented Polypropylene) laminated bags. These bags not only offer enhanced durability but also contribute to reducing the carbon footprint associated with packaging.

Understanding BOPP Bags

What Are BOPP Bags?

BOPP bags are made from woven polypropylene fabric coated with a biaxially oriented polypropylene film. This lamination process imparts additional strength, moisture resistance, and a glossy finish, making them ideal for packaging various products, including food grains, fertilizers, and industrial materials.

Advantages of BOPP Bags

-

Enhanced Durability: The BOPP coating provides added strength, making the bags resistant to tearing and puncturing.srindustryindia.com

-

Moisture and Dust Resistance: The lamination offers excellent protection against moisture and dust, preserving the quality of the contents.wstpackaging.com+4srindustryindia.com+4xifagroup.com+4

-

High-Resolution Printing: Allows for vibrant prints and graphics, enhancing branding and product visibility.

Baheti Group’s Commitment to Sustainability

Vision and Mission

Baheti Group’s vision is to provide quality products at competitive rates with on-time delivery and to be a global leader in the field of polymer-based products. Their mission emphasizes initiating employment opportunities and focusing on people’s well-being through green initiatives.

Sustainable Practices in Manufacturing

Baheti Group integrates sustainability into its operations by adopting eco-friendly manufacturing processes. They utilize energy-efficient technologies and minimize waste generation during production, aligning with their commitment to environmental responsibility.

Recycling Initiatives

Through Baheti Recycling Industries Limited, the group engages in recycling practices that reduce greenhouse gas emissions and conserve natural resources. Their efforts in recycling aluminum scrap into fine aluminum products exemplify their dedication to sustainable practices.

Environmental Impact of BOPP Bags

Reduction in Carbon Footprint

The production of BOPP bags involves less energy consumption compared to other packaging materials, leading to a reduction in carbon emissions. Additionally, their lightweight nature reduces transportation energy requirements, further minimizing the carbon footprint.

Contribution to Circular Economy

BOPP bags are recyclable, contributing to a circular economy where materials are reused, reducing the need for virgin resources. Baheti Group’s emphasis on recyclability ensures that their products align with sustainable practices.

ndustry Applications of BOPP Bags

Agriculture

In agriculture, BOPP bags are used for packaging seeds, fertilizers, and pesticides. Their moisture resistance and durability ensure the protection of agricultural inputs, enhancing productivity and reducing waste.

Food Grains

For packaging food grains, BOPP bags offer a hygienic and durable solution. The high-resolution printing capability allows for clear labeling, ensuring compliance with food safety standards.

Industrial Materials

BOPP bags are also utilized in packaging industrial materials such as chemicals and construction products. Their strength and resistance to environmental factors make them suitable for various industrial applications.

Baheti Group’s Market Reach

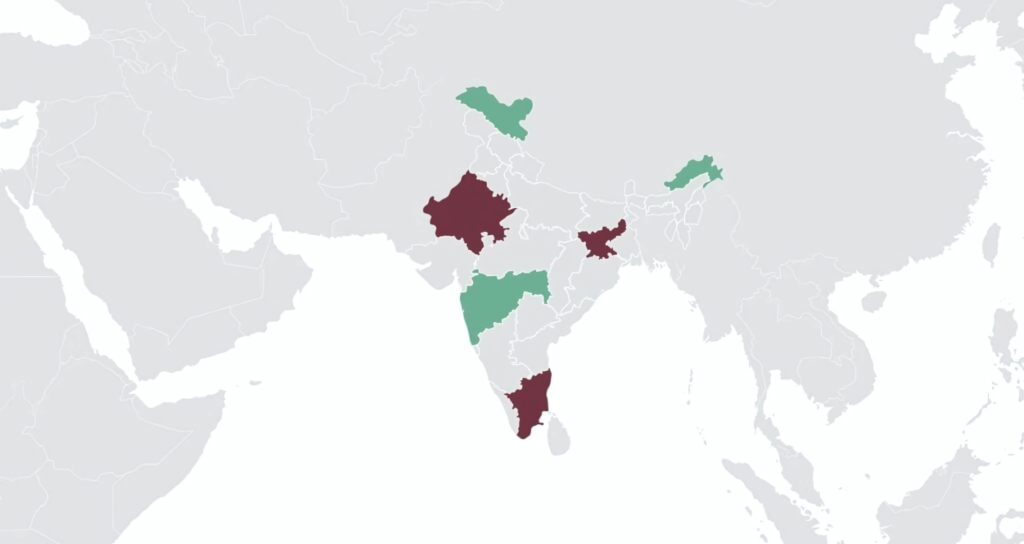

Baheti Group serves approximately 60,000 tonnes annually to buyers across various locations in India, including Ahmedabad, Bangalore, New Delhi, Erode, Haryana, Hyderabad, Jaipur, Ludhiana, Mumbai, Rajasthan, and Surat. Their extensive market reach underscores their commitment to providing quality and sustainable packaging solutions nationwide.

Future Directions in Sustainable Packaging

Research and Development

Baheti Group continues to invest in research and development to innovate and improve their packaging solutions. This includes exploring alternative materials and technologies that further reduce environmental impact.

Collaboration with Stakeholders

The group collaborates with suppliers, customers, and industry experts to promote sustainability across the supply chain. These partnerships facilitate the adoption of best practices and the development of eco-friendly packaging solutions.

Read More:- Are BOPP Woven Bags Eco-Friendly?

Conclusion

Baheti Group’s adoption of BOPP laminated bags exemplifies their commitment to sustainability in the packaging industry. Through eco-friendly manufacturing practices, recycling initiatives, and a focus on reducing carbon emissions, they are setting a benchmark for sustainable packaging solutions. Their efforts not only contribute to environmental conservation but also offer businesses a reliable and eco-friendly alternative for packaging needs.