Why BOPP Woven Bags Are the Future of Packaging

In an age of increasing environmental awareness and demand for sustainable alternatives, businesses are actively seeking eco-friendly packaging solutions that balance performance with responsibility. Among the various options available today, BOPP woven bags have emerged as a game-changer in the packaging industry.

This article explores what makes BOPP woven bags an ideal choice for green packaging and why they are poised to lead the future of sustainable logistics, agriculture, and retail packaging.

What Are BOPP Woven Bags?

Understanding BOPP Film

BOPP stands for Biaxially Oriented Polypropylene, a type of film stretched in both machine and transverse directions to enhance strength, clarity, and barrier properties.

Woven Polypropylene Base

The base of the bag is made from woven polypropylene fabric, giving the bag structural strength, durability, and high load-bearing capacity.

Laminated Design

BOPP film is laminated onto the woven polypropylene fabric, resulting in a bag that is not only strong but also resistant to moisture, UV rays, and tearing.

Read More :- Recyclable vs. Reusable: BOPP Woven Bags Explained

Advantages of BOPP Woven Bags in Green Packaging

1. Reusability and Longevity

Unlike single-use plastic or paper bags, BOPP woven bags can be reused multiple times. Their durability makes them ideal for applications that require long-lasting performance, such as grain storage or cement packaging.

2. Recyclable Material

Both the woven PP fabric and BOPP film are recyclable. Although they need to be separated in specialized facilities, the process supports circular economy principles.

3. Lower Carbon Footprint

The production of BOPP woven bags consumes less energy compared to many traditional plastic or paper-based packaging products. This contributes to a lower carbon footprint over the life cycle of the product.

4. Lightweight but Strong

The lightweight nature of these bags means reduced transportation costs and emissions, while their strength ensures they can hold heavy items without damage.

5. Water and Moisture Resistance

Thanks to the laminated BOPP film, these bags offer excellent protection against water and moisture—crucial for agricultural and industrial use where goods need to remain dry.

6. Superior Print Quality for Branding

The glossy surface of BOPP film allows for high-resolution printing, making it easier for companies to display vibrant, eco-friendly branding without additional materials or labels.

BOPP Woven Bags vs. Traditional Packaging

| Feature | BOPP Woven Bags | Paper Bags | Plastic Bags |

|---|---|---|---|

| Durability | High | Low to Medium | Low |

| Reusability | Yes | No | No |

| Recyclable | Yes | Yes | Often No |

| Moisture Resistance | Excellent | Poor | Poor |

| Branding | Excellent | Average | Poor |

| Cost-Efficiency | High | Low | Medium |

This comparison clearly shows that BOPP woven bags outperform traditional alternatives in most environmental and functional metrics

Applications of BOPP Woven Bags Across Industries

1. Agriculture

BOPP woven bags are ideal for storing and transporting grains, seeds, fertilizers, and animal feed. Their resistance to pests and moisture ensures product safety.

2. Retail & E-commerce

More businesses are switching to custom-printed BOPP bags for carrying groceries, garments, or goods. They combine visual appeal with green credentials.

3. Industrial Use

Used for packaging cement, sand, chemicals, and minerals, BOPP woven bags offer unmatched strength and resistance under harsh conditions.

4. Food Packaging

Due to their food-safe materials and barrier protection, BOPP bags are also suitable for items like rice, flour, sugar, and pulses.

How BOPP Woven Bags Support Sustainability Goals

1. Reducing Single-Use Plastics

By offering a reusable alternative, BOPP woven bags help in reducing the reliance on harmful single-use plastic bags.

2. Supporting Recycling Infrastructure

Their compatibility with existing plastic recycling systems encourages industries to streamline packaging disposal in an eco-responsible way.

3. Encouraging Conscious Consumer Behavior

When businesses adopt sustainable packaging, consumers are more likely to trust and support brands that prioritize environmental responsibility.

Challenges in Adoption (and How to Overcome Them)

1. Recycling Complexity

Since BOPP bags are laminated, they require separation before recycling. Solutions include investment in recycling tech or promoting upcycling.

2. Initial Cost Perception

Although slightly more expensive upfront than conventional plastic bags, the long-term value in durability and branding outweighs the cost.

3. Lack of Awareness

Some industries are still unaware of the benefits. Education, government incentives, and industry case studies can help bridge this gap.

Case Studies: Success with BOPP Woven Bags

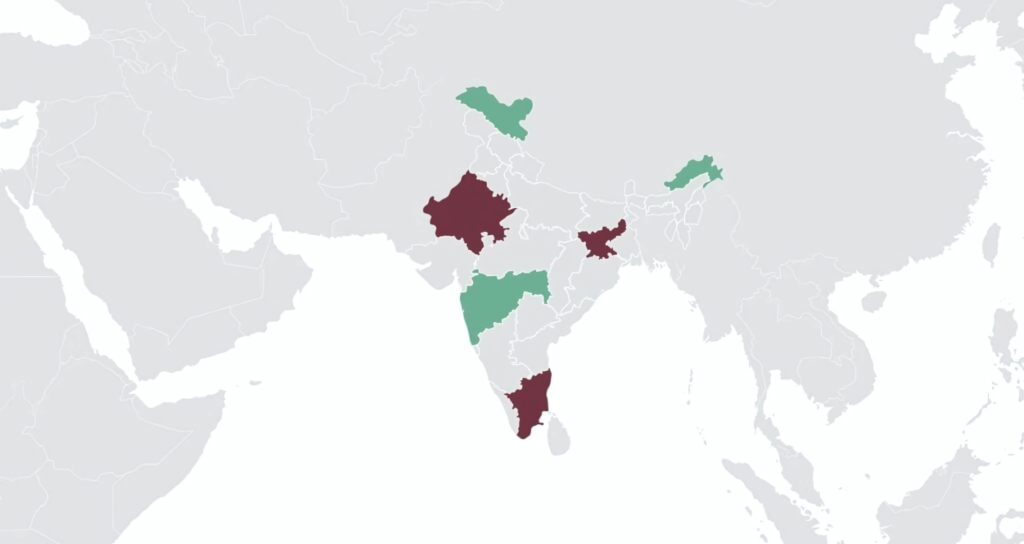

Case 1: Agriculture Company in India

A leading grain exporter replaced their traditional jute sacks with BOPP woven bags, reducing product loss by 30% and cutting transportation costs by 15%.

Case 2: Cement Manufacturer in Europe

A cement company shifted to BOPP bags and experienced enhanced brand recognition, increased retail shelf life, and 25% fewer complaints about damaged packaging.

How to Choose the Right BOPP Woven Bag Supplier

When selecting a supplier for BOPP woven bags, consider the following:

-

Quality certifications (ISO, food-grade compliance)

-

Printing capabilities for custom branding

-

Minimum order quantities

-

Lead times and production capacity

-

Sustainability credentials

Choosing a reliable supplier ensures you get the full benefits of switching to BOPP woven bags without compromising on timelines or quality.

Future Trends in BOPP Packaging

1. Integration with Smart Packaging

QR codes and RFID technology can be printed on BOPP bags to track inventory and interact with customers.

2. Biodegradable Additives

New innovations are exploring biodegradable or compostable layers to further enhance environmental performance.

3. Expansion into Luxury and Fashion

As aesthetics improve, BOPP woven bags are increasingly entering high-end retail markets as eco-chic packaging solutions.

Conclusion: A Green Packaging Future with BOPP Woven Bags

As environmental concerns reshape global trade and consumer behavior, the demand for green packaging continues to grow. BOPP woven bags offer an effective, sustainable, and economically viable solution that balances durability, brand appeal, and eco-friendliness.

By adopting BOPP woven bags, companies not only reduce their environmental impact but also position themselves as responsible, future-ready brands. It’s time to embrace the change and lead the way toward a cleaner, greener packaging future.